Q-Leap is a truly vertically integrated manufacturing facility

Our Capabilities

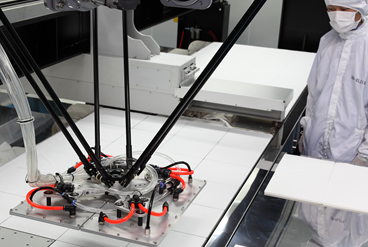

Established in 2001, Q-Leap has a manufacturing facility over 100,000 sq. feet with over 50,000 sq. feet allotted to the ISO Class 10/100/1000 cleanrooms. Through continuous process improvements and investments, Q-Leap has become the first truly vertically integrated cleanroom consumables manufacturing facility. We have implemented robotic automation into our processes to eliminate human source contamination. With the support of the Materials and Process Testing Center, our engineering and management teams have been awarded multiple patents and recognition. Q-Leap tailors for you product customization and new product development.