Wipers

Wiper Cleaning Principle

Cleaning is a process of lowering the adhesion force between the particles and the surface to be cleaned allowing the contaminant to be easily captured by the wiper. It involves a method of balancing the particle content between the contaminated surface and the wiper. Volatile solvents such as alcohol which exhibit low surface tension are often used to lower the particle adhesion force to the surface. These solvents also remove organic oils presented to the surface. Wiping action is to let the solvent wetted wiper remove and absorb contaminants from the surface into the wiper until desirable cleanliness level is achieved.

Cleanroom Non-Woven Wiper Series

POLYCELLULOSE NON-WOVEN WIPER

• 50% Cellulose, 50% Polyester

• High Absorptive Capacity

• USP 797 Compatible

• Processed in a controlled environment

• Light Duty: 50 g/m2

![]() Light Duty: 50 g/m2

Technical Data Sheet (PDF Format)

Light Duty: 50 g/m2

Technical Data Sheet (PDF Format)

![]() Medium Duty: 60 g/m2

Technical Data Sheet (PDF Format)

Medium Duty: 60 g/m2

Technical Data Sheet (PDF Format)

![]() Heavy Duty: 68 g/m2

Technical Data Sheet (PDF Format)

Heavy Duty: 68 g/m2

Technical Data Sheet (PDF Format)

| Non-Woven Wipers (Light Duty: 50g/m2, Medium Duty: 60g/m2, Heavy Duty: 68g/m2) | |||||||||

| Part No. | Size | Packing Spec | BGS/Case | PCS/Case | |||||

| Pcs/Pack | Packs/Bag | ||||||||

|

4"X 4" | 300 | 4 | 10 | 12,000 | ||||

|

6"X6" | 150 | 2 | 20 | 6,000 | ||||

|

9"X 9 " | 150 | 2 | 10 | 3,000 | ||||

|

12"X 12 " | 150 | 1 | 10 | 15,000 | ||||

Cleanroom Knitted Wipers Series

- Pylon – Advanced Blend Knitted Wipers

- Knitted Polyester Wipers

- Knitted Polyester Micro-Fiber Wipers

- Knitted Polyester-Nylon Composite Micro-Fiber Wipers

PYLON - ADVANCED BLEND KNITTED WIPERS

Features:

• Quantum Processed®

• Solvent resistant

• High absorptive capacity and absorption rate

• USP <797> compliant

• Double –Knitted

• 150 pieces/inner bag, easy - tear outer bag (10 bags/case for 9”x9”, 6 bags/case for

12”x12”)

Product No. QL-SH809G-LE9”x9”, QL-SH812G-LE 12”x12”

Product Description: Pylon® Wiper, Microfiber & Polyester Blend,

Laser cut edge.

![]() Pylon Wiper Technical Data

Sheet (PDF Format)

Pylon Wiper Technical Data

Sheet (PDF Format)

Applications:

• Cleanroom Class ISO 5 – 8 environment; ISO 4 option available upon request

• Used to dry wet surfaces and remove contaminants

• Autoclavable

| Property | Typical Value | Test Method | Remarks |

| Basis Weight | 135 g/m2 | SJ/T 11480-2014 4.3 | |

| Thickness | 0.4 mm | GB/T 24218.2-2009 | |

| Sorptive Capacity | 341.5 ml/m2 | IEST-RP-CC004.3 (2004) 8.1, 8.2 | |

| Sorptive Rate (IPA) | 0.59 sec. | IEST-RP-CC004.3 (2004) 8.1, 8.2 |

| Property | Typical Value | Test Method | Remarks |

| LPC ≥ 0.5 μm | 513 particles/cm2 | IEST-RP-CC004.3(2004) 6.1.4 | |

| APC ≥ 0.3 μm | 14 counts/9”x9” piece | IEST-RP-CC003.4 (2011) B2.4 | |

| APC ≥ 0.5 μm | 11 counts/9”x9” piece | IEST-RP-CC003.4 (2011) B2.4 | |

| APC ≥ 1.0 μm | 8 counts/9”x9” piece | IEST-RP-CC003.4 (2011) B2.4 | |

| NVR (IPA) | 0.176 mg/g | IEST-RP-CC004.3 (2004) 7.1.2 | |

| NVR (DIW) | 0.0625 mg/g | IEST-RP-CC004.3 (2004) 7.1.2 | |

| Sodium⁺ | 0.224 ppm | IEST-RP-CC004.3 (2004) 7.2.2 | MDL = .001ppm |

| Potassium⁺ | 0.142 ppm | EST-RP-CC004.3 (2004) 7.2.2 | MDL = .001 ppm |

| Chloride⁻ | 0.229 ppm | IEST-RP-CC004.3 (2004) 7.2.2 | MDL = .001 ppm |

Note: Data in this table represents typical analyses of these wipers at time of publication. Based on test report no. SUO130708001.

Q-Leap lab meets ISO 17025 Standards for testing cleanroom materials.

Q-Leap production facility is ISO 9001:2008 and ISO 14001:2004 certified.

PYLON - ADVANCED BLEND KNITTED WIPERS - DOUBLE PYLON

Features:

• Quantum Processed®

• Solvent resistant

• High absorptive capacity and absorption rate

• USP <797> compliant

• Double –Knitted, ultrasonic welded 2-ply structure

• 75 pieces/inner bag, easy-tear outer bag, 10 bags/case, 750 pieces/case

Product No. DP-SH809G-LE

Product Description: Double Ply Pylon® Wiper, 2-ply 9” x 9”, Microfiber &

Polyester Blend, Laser cut edge.

![]() Pylon Wiper

Technical Data Sheet (PDF Format)

Pylon Wiper

Technical Data Sheet (PDF Format)

Applications:

• Cleanroom Class ISO 5 – 8 environment, ISO 4 option available upon request

• Used to dry wet surfaces and remove contaminants

• Autoclavable

| Property | Typical Value | Test Method | Remarks |

| Basis Weight | 270 g/m2 | SJ/T 11480-2014 4.3 | |

| Thickness | 0.8 mm | GB/T 24218.2-2009 | |

| Sorptive Capacity | 642 ml/m2 | IEST-RP-CC004.3 (2004) 8.1, 8.2 | |

| Sorptive Rate (IPA) | 0.44 sec. | IEST-RP-CC004.3 (2004) 8.1, 8.2 |

| Property | Typical Value | Test Method | Remarks |

| LPC ≥ 0.5 μm | 725 particles/cm2 | IEST-RP-CC004.3(2004) 6.1.4 | |

| APC ≥ 0.5 μm | 6 counts/9”x9” piece | IEST-RP-CC003.4 (2011) B2.4 | |

| NVR (IPA) | 0.2491 mg/g | IEST-RP-CC004.3 (2004) 7.1.2 | |

| Silicon | ND | IEST-RP-CC004.3 (2004) 7.2.1 | |

| Amine | ND | IEST-RP-CC004.3 (2004) 7.2.1 | |

| DOP | ND | IEST-RP-CC004.3 (2004) 7.2.1 | |

| Sulphate | 0.209 ppm | IEST-RP-CC004.3 (2004) 7.2.2 | MDL = .001 ppm |

| Chloride | 0.065 ppm | IEST-RP-CC004.3 (2004) 7.2.2 | MDL = .001 ppm |

Note: Data in this table represents typical analyses of these wipers at time of publication.

Q-Leap lab meets ISO 17025 Standards for testing cleanroom materials.

Q-Leap production facility is ISO 9001:2008 and ISO 14001:2004 certified.

PYLON - ADVANCED BLEND KNITTED WIPERS - HEAVY PYLON

Features:

• Quantum Processed®

• Solvent resistant

• High absorptive capacity and absorption rate

• USP <797> compliant

• Double –Knitted

• 150 pieces/inner bag, easy-tear outer bag, 10 bags/case, 1500 pieces/case

Product No. QL-SH809L-LE

Product Description: Heavy Weight Pylon® Wiper, 9” x 9”, Microfiber &

Polyester Blend, Laser cut edge.

![]() Pylon Wiper

Technical Data Sheet (PDF Format)

Pylon Wiper

Technical Data Sheet (PDF Format)

Applications:

• Cleanroom Class ISO 5 – 8 environment, ISO 4 option available upon request

• Used to dry wet surfaces and remove contaminants

• Autoclavable

| Property | Typical Value | Test Method | Remarks |

| Basis Weight | 165 + 12 g/m2 | SJ/T 11480-2014 4.3 | |

| Sorptive Capacity | 303.6 ml/m2 | IEST-RP-CC004.3 (2004) 8.1, 8.2 | |

| Sorptive Rate (IPA) | 0.57 sec. | IEST-RP-CC004.3 (2004) 8.1, 8.2 |

| Property | Typical Value | Test Method | Remarks |

| LPC ≥ 0.5 μm | 723 particles/cm2 | IEST-RP-CC004.3(2004) 6.1.4 | |

| APC ≥ 0.5 μm | 14 counts/9”x9” piece | IEST-RP-CC003.4 (2011) B2.4 | |

| NVR (IPA) | 0.1626 mg/g | IEST-RP-CC004.3 (2004) 7.1.2 | |

| Silicon | ND | IEST-RP-CC004.3 (2004) 7.2.1 | |

| Amine | ND | IEST-RP-CC004.3 (2004) 7.2.1 | |

| DOP | ND | IEST-RP-CC004.3 (2004) 7.2.1 | |

| Sulphate | 0.108 ppm | IEST-RP-CC004.3 (2004) 7.2.2 | MDL = .001 ppm |

| Chloride | 0.021 ppm | IEST-RP-CC004.3 (2004) 7.2.2 | MDL = .001 ppm |

Note: Data in this table represents typical analyses of these wipers at time of publication.

Q-Leap lab meets ISO 17025 Standards for testing cleanroom materials.

Q-Leap production facility is ISO 9001:2008 and ISO 14001:2004 certified.

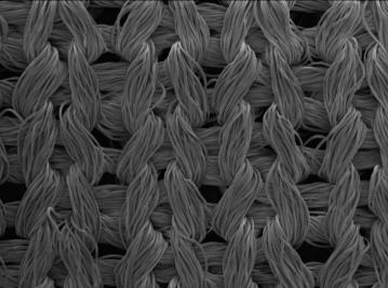

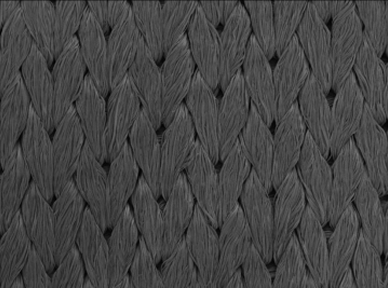

KNITTED POLYESTER WIPERS

• 100% Polyester

• Manufactured using Proprietary Quantum Process

• Low Particle Generation

• High Abrasion Resistance

• Cleanroom Processed and Packaged

• Processed in ISO-9001 & ISO-14001 Certified Cleanroom Facilities

• Sterile and Pre-Saturated Options Available

|

|

| Mesh Grain | Line Grain |

| Part Number | Weight (g/m2) | Knitting Method | Part Number | Weight (g/m2) | Knitting Method |

| 1009A |

150 | Mesh grain | 1009K | 180 | Mesh grain |

| 10098 | 115 | Mesh grain | 2009D | 140 | Line Grain |

| 1009C | 155 | Mesh grain | 2009F | 128 | Line Grain |

| 1009D | 125 | Mesh grain | QL-3009D |

120 | Line Grain |

| 1009F | 135 | Mesh grain | 4009E | 125 | Line Grain |

| 1009S |

160 | Mesh grain | 5009 | 180 | Line Grain |

| Size | Pcs/Inner Bag | Pcs/Outer Bag |

| 4 " x 4 " | 150 | 600 |

| 6 " x 6 " | 150 | 150 |

| 9 " x 9 " | 150 | 150 |

| 12 " x 12 " | 150 | 150 |

KNITTED POLYESTER MICRO-FIBER WIPERS

• Manufactured using Proprietary Quantum Process

• 100% Polyester

• High Absorptive Capacity

• Cleanroom processed and packaged

• Processed in ISO-9001 & ISO-14001 Certified Cleanroom Facilities

| Part Number | Weight (g/m2) | Knitting Method | Part Number | Weight (g/m2) | Knitting Method |

| 4009A | 165 | Line grain | 4009D | 130 | Line grain |

| 4009C | 100 | Line grain |

| Size | Pcs/Inner Bag | Pcs/Outer Bag |

| 4 " x 4 " | 150 | 600 |

| 6 " x 6 " | 150 | 150 |

| 9 " x 9 " | 150 | 150 |

| 12 " x 12 " | 150 | 150 |

KNITTED POLYESTER-NYLON COMPOSITE MICRO-FIBER WIPERS

• Polyester-Nylon Composite

• Manufactured using Proprietary Quantum Process

• Superior Absorptive Capacity

• Cleanroom processed and packaged

• Processed in ISO-9001 & ISO-14001 Certified Cleanroom Facilities

| Part Number | Weight (g/m2) | Knitting Method | Part Number | Weight (g/m2) | Knitting Method |

| 5009D | 165 | Line grain | HK509C | 140 | Line grain |

| 6009D | 180 | Line grain | HK6009 | 200 | Line grain |

| 8009D | 210 | Line grain | HK7009 | 180 | Line grain |

| 9009D | 200 | Line grain | HK8009 | 210 | Line grain |

| Size | Pcs/Inner Bag | Pcs/Outer Bag |

| 4 " x 4 " | 400 | 400 |

| 6 " x 6 " | 100 | 100 |

| 9 " x 9 " | 100 | 100 |

| 12 " x 12 " | 100 | 100 |